BuyCo for Inbound Logistics:

Gain Control, Cut Costs, and Streamline Container Shipping

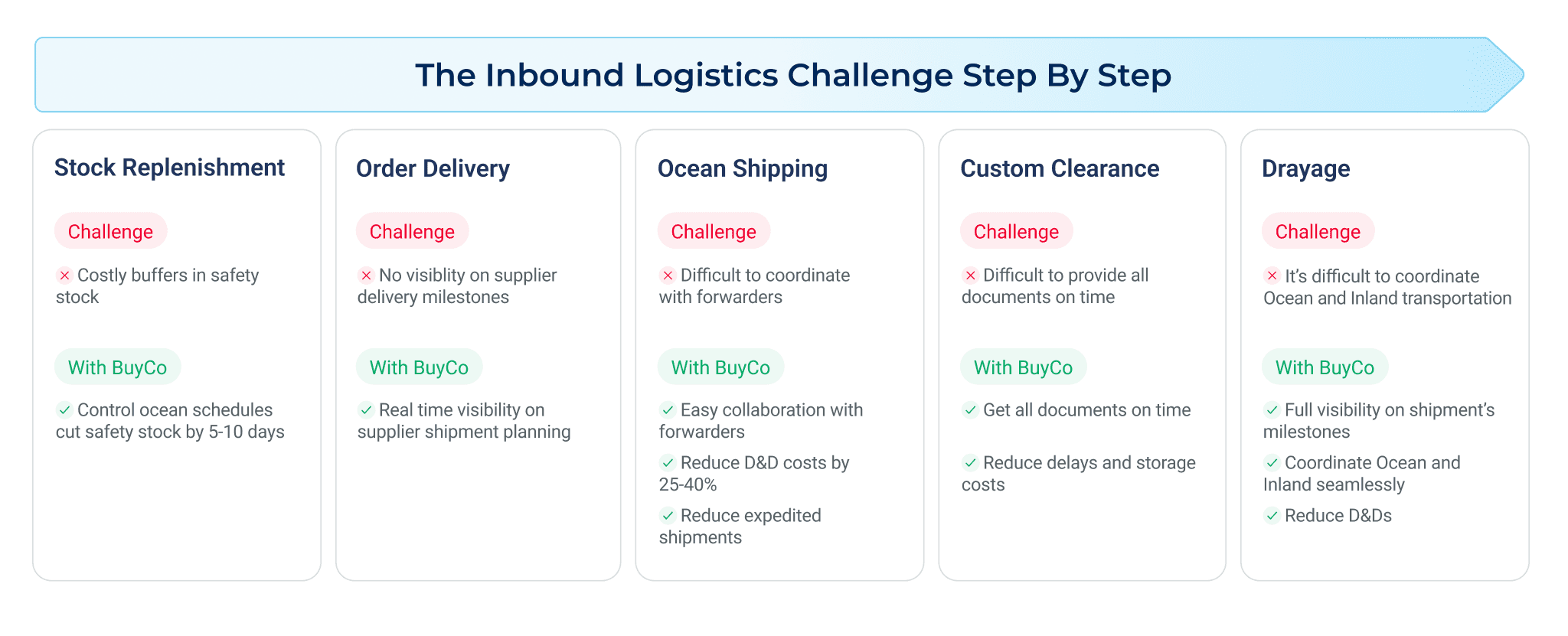

Inbound logistics teams spend 60-70% of time on manual communication and document tracking instead of strategic decision-making. BuyCo’s collaborative platform centralizes operations, automates workflows, and delivers end-to-end control from origin to warehouse.

Full Control Over Deliveries from Origin to Warehouse

Information silos cost money:

• demurrage and detention charges of $200-300 per container daily

• expedited shipments at 300-400% premium rates

• safety stock inflated by 30-50%

A typical inbound container shipment involves 15-20 communication touchpoints across 5-7 stakeholders when these rely on email and disconnected systems, delays compound.

BuyCo’s collaborative platform delivers:

- Centralized container shipment records as a single source of truth, reducing communication time by 75%.

- Synchronized workflows across freight forwarders, shipping lines, customs, inland transport, and warehouse cutting D&D costs by 25-40% and eliminating 80% of expedited shipments.

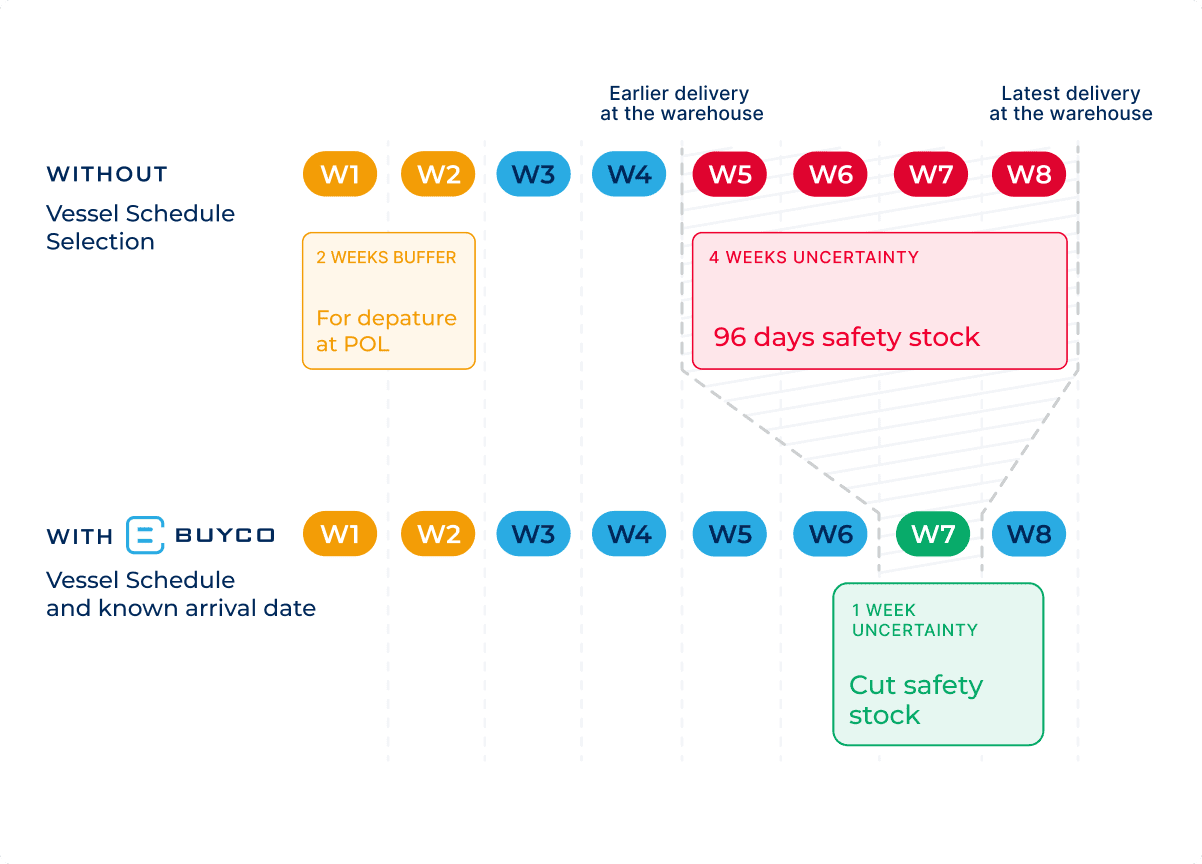

- Lead time control through vessel schedule selection, reducing safety stock requirements by 30-50%.

Control ocean freight schedules instead of defaulting to forwarder selections. Align vessel arrivals with production schedules, warehouse capacity, and inventory cycles: transform logistics from reactive firefighting to strategic planning.

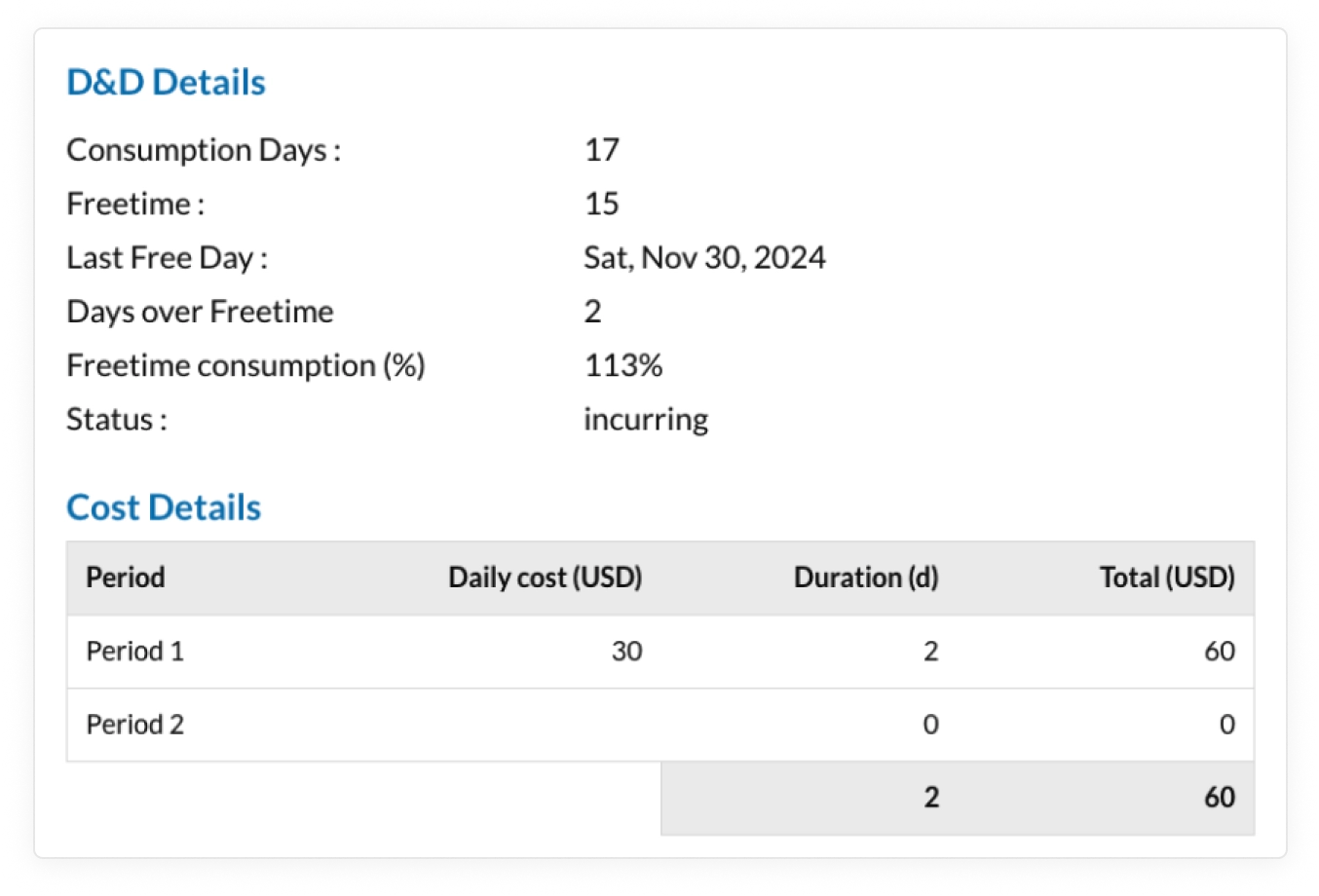

Reduce Costs You Shouldn’t Be Paying

Shipping friction generates avoidable costs:

• 15-20% of containers incur D&D charges

• 10-15% require expedited delivery (3-4x standard rates)

• dry runs cost $150-250 per failed pickup

• manual coordination consumes 11+ hours per shipment

BuyCo eliminates these costs through:

- Central repository for all shipments, eliminating data fragmentation causing coordination failures

- Automated shipment records via ERP integration or AI extraction, reducing manual entry by 85%

- Collaborative workspaces for real-time operations

- Demurrage & Detention Control Panel; stop fees before they start

- 3-month implementation delivering measurable ROI in the first quarter

Shift from monitoring 100% of operations manually to exception-based management focused on the 10-15% of shipments requiring intervention.

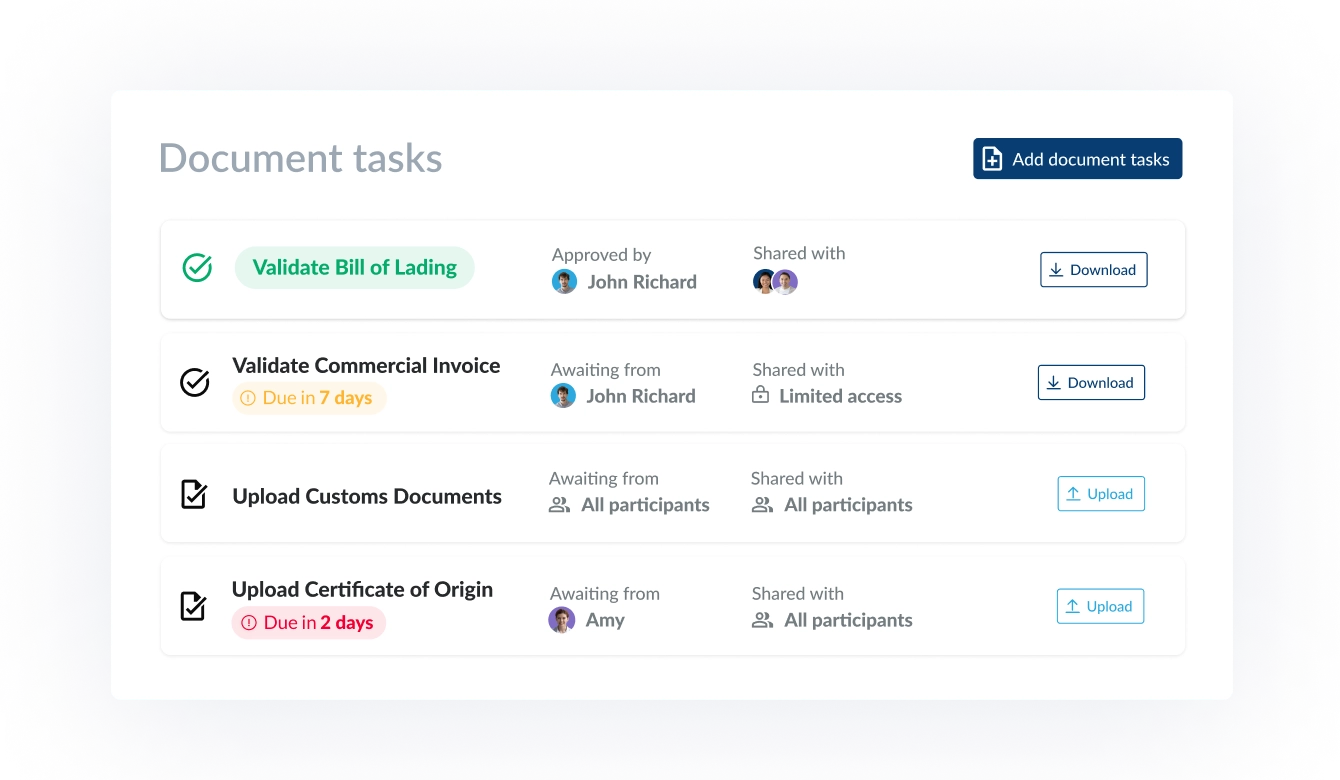

Streamline Customs Clearance

Missing or late documentation delays clearance, triggering storage charges and compounding demurrage fees. Without structured workflows, customs brokers receive complete documentation for only 60-70% of shipments on first submission.

BuyCo streamlines customs through:

- Automated document workflows tracking completion status ensuring 95%+ on-time availability

- Exception-based alerts notifying teams only when documents are missing—reducing monitoring time by 80%

- Audit trails with timestamped uploads and version control supporting compliance and dispute resolution

Result: 30-40% faster customs clearance, reduced port dwell time, and lower storage costs.

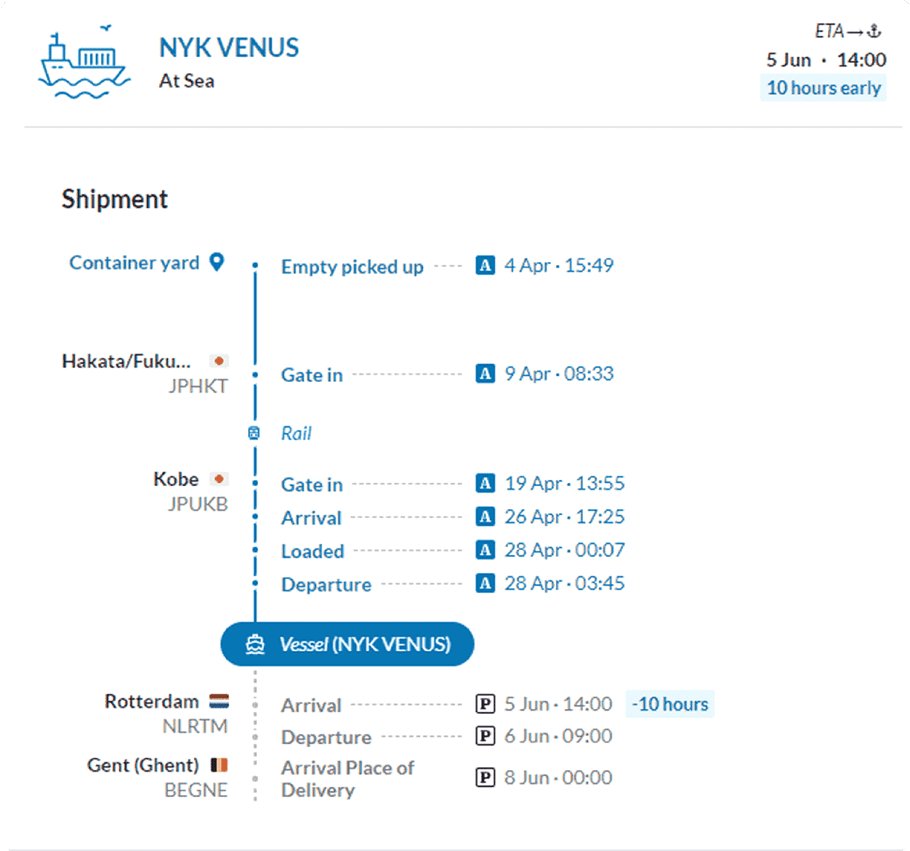

Orchestrate Ocean to Inland to Warehouse Transport

Handoffs between ocean arrival and inland delivery involve vessel operators, terminals, customs, drayage carriers, rail/barge providers, and warehouses. Each transition introduces disruptions when information doesn’t flow seamlessly.

- Schedule and track shipments from origin through final delivery with milestone-based visibility across all modes

- Monitor vessel arrivals and customs status to trigger optimal drayage dispatch reducing pickup delays by 40-50%

- Assign inland carriers with automated dispatch notifications and pickup instructions

- Centralize communication across all stakeholders for coordinated appointment scheduling

- Integrate ocean and inland legs in unified records synchronizing schedules, tracking, and documentation

- Streamline ocean-to-inland transitions and eliminate avoidable charges through digitalized workflows and complete control of container flows.

Reduce Safety Stock Requirements

Ocean transit times for the same route vary by 40-60% (21 vs. 35 days) based on vessel selection, transshipment, and congestion. This forces safety stock holdings at 1.5 to 2 times the lead time standard deviation.

When forwarders control vessel selection, importers accept lead time variability 2 to 3 times higher than necessary, and the corresponding safety stock requirements.

Experience the benefits of BuyCo’s collaborative platform:

- Automated document workflows tracking completion status ensuring 95%+ on-time availability

- Exception-based alerts notifying teams only when documents are missing, reducing monitoring time by 80%

- Schedule optimization algorithms, recommend best carrier/vessel/routing based on cargo ready and delivery dates

Result:

Proactive schedule selection enables importers to align arrivals with shorter replenishment cycles:

• 15-25% lead time reduction,

• 40-60% variability reduction,

• 30-50% safety stock reduction while maintaining service levels.

For 1,000 TEU annually at $50,000 per container:

• $7.5-12.5M working capital reduction.

Optimize Your Team’s Efficiency

Traditional logistics coordination involves high manual workload, tracking across forwarders and carrier sites, chasing documents, updating spreadsheets, responding to inquiries. This burden drives insatisfaction in coordination roles. Give your team the digital platform they deserve and your business the competitive edge it needs.

- Happier Teams: Eliminate tedious manual work and boost satisfaction

- Easier Hiring: Attract top talent with modern, powerful technology

- Operational Excellence: Orchestrate complex shipping with confidence