Inbound logistics, the process of moving goods from your suppliers to your warehouse, is one of the most complex and cost-sensitive areas of supply chain management. For retailers, (and more broadly, importers), poor inbound management isn’t just an operational headache. It ties up working capital, drives detention and demurrage (D&D) fees, inflates safety stock, and creates daily firefighting for your team.

Most retailers carry far more safety stock than they actually need, tying up capital and inflating costs across the supply chain. On top of that, they spend 60 to 70% of their time manually tracking shipments, chasing documents, and coordinating multiple stakeholders. These inefficiencies often create additional, avoidable expenses, from detention and demurrage to unnecessary forwarding fees. The good news is that all of these challenges can be addressed.

In this guide, we break down the five critical steps of inbound logistics, highlight the pain points at each stage, and show how modern digital tools and smarter workflows can help retailers reduce stock, save time, and cut unnecessary costs.

What Are Inbound Logistics?

Inbound logistics is the process of bringing materials, components, or finished goods from suppliers into your business. For retailers, this includes:

- Purchasing and placing orders

- Managing supplier shipments

- Coordinating ocean and inland transportation

- Handling customs clearance

- Receiving goods and updating inventory systems

Inbound logistics focuses on the supply side of the supply-and-demand equation, ensuring the right product arrives at the right place, on time, and at the lowest total cost.

Why Inbound Logistics Is Challenging for Retailers

Managing inbound shipments is anything but simple. Behind every container lies a complex network of processes, stakeholders, and data, and two main challenges make it even more difficult: reliance on external logistics providers and manual tasks.

The Two Key Challenges

1. Reliance on External Logistics Providers

Many retailers outsource logistics to freight forwarders and other service providers. While this can simplify operations, it often limits visibility and control over inbound shipments and lead time. Without direct oversight, it becomes harder to optimize logistics flows, leading to higher inventory costs and avoidable charges such as detention and demurrage.

2. Information Silos

Inbound logistics still involves countless manual steps, from spreadsheets and emails to phone calls. Teams spend hours tracking shipments and coordinating stakeholders instead of focusing on higher-value work. These manual processes increase the likelihood of errors, which in turn drive additional costs through exception handling and reactive problem-solving.

The Ripple Effects

These challenges lead to:

- Higher Costs: Expedited shipments, Detention & Demurrage fees, and safety stocks erode margins.

- Delays: Missing or late documentation, hours waisted in manual workload lead to late shipments with a direct impact on the production and customer satisfaction.

- Demotivated Teams: Employees spend time on low value added tasks instead of strategic work, lowering engagement.

Challenges in inbound logistics can slow your supply chain and impact performance. Digitization turns these challenges into opportunities by streamlining every critical step.

Mastering the 5 Critical Steps of Inbound Logistics

Inbound logistics can make or break your supply chain. From ordering stock to final delivery, every step comes with challenges, delays, and hidden costs. Here are the 5 critical steps every importer should master and how digital platforms like BuyCo become your ally.

Step 1: Stock Replenishment

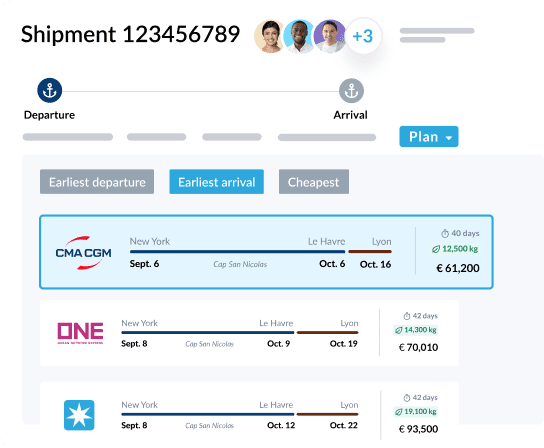

Challenge: Retailers often face unpredictable arrival dates because they have limited visibility and control over shipments, which are managed by their forwarders. Transit times for the same route can vary by 40% to 60% due to vessel selection, transshipment, and port congestion. Without insight into schedules, teams hold excessive inventory sometimes, 1.5 to 2 times higher than normal lead-time variability, to avoid stockouts.

Consequences: High working capital tied up in inventory, increased storage costs, and delayed production cycles. Teams scramble to manage uncertainty instead of planning strategically.

How Digital Platforms Like BuyCo Help: Execution-aware systems provide visibility into vessel schedules and transit times, enabling importers to select vessels that align with production schedules and warehouse capacity. Reducing lead time variability allows safety stock to drop from 30 to 50%, freeing working capital.

→ Learn more about how to reduce working capital with full control on transportation lead time.

Step 2: Order Delivery

Challenge: Retailers often don’t know when suppliers will ship or whether a shipment is actually booked. Manual tracking across emails, spreadsheets, and phone calls creates fragmented information and leads to missed milestones.

Consequences: A lack of visibility on deliveries disrupts business workflows and significantly impacts the customer experience. Rush shipments at premium costs become routine.

How Digital Platforms Like BuyCo Help: Collaborative platforms like BuyCo consolidate supplier updates into a single source of truth. Real-time alerts allow importers to spot delays before they become costly.

Step 3: Ocean Shipping

Challenge: Coordinating containers from suppliers with multiple forwarders is complex. Misaligned schedules, fragmented communication increase D&D and expedited costs. In fact 15 to 20% of containers incur D&D and 10 to 15% require expedited shipping. On top of that, enabling suppliers to book transport with your forwarders at your negotiated carrier rates is far from straightforward.

Consequences: Unnecessarily high logistics costs.

How Digital Platforms Like BuyCo Help: Digital platforms centralize communication across all supply chain stakeholders, benchmark carriers and forwarders, and prioritize high-impact shipments. They also enable you to share tendered carrier options directly with suppliers.

As a result, D&D costs can drop by 25–40%, and up to 80% of expedited shipments can be avoided.

Step 4: Customs Clearance

Challenge: Missing or late documentation is a major bottleneck. Only 60–70% of shipments reach customs brokers with complete documentation on first submission.

Consequences: Delays at the port, increased storage fees, and rising D&D costs. Teams spend hours chasing documents instead of planning.

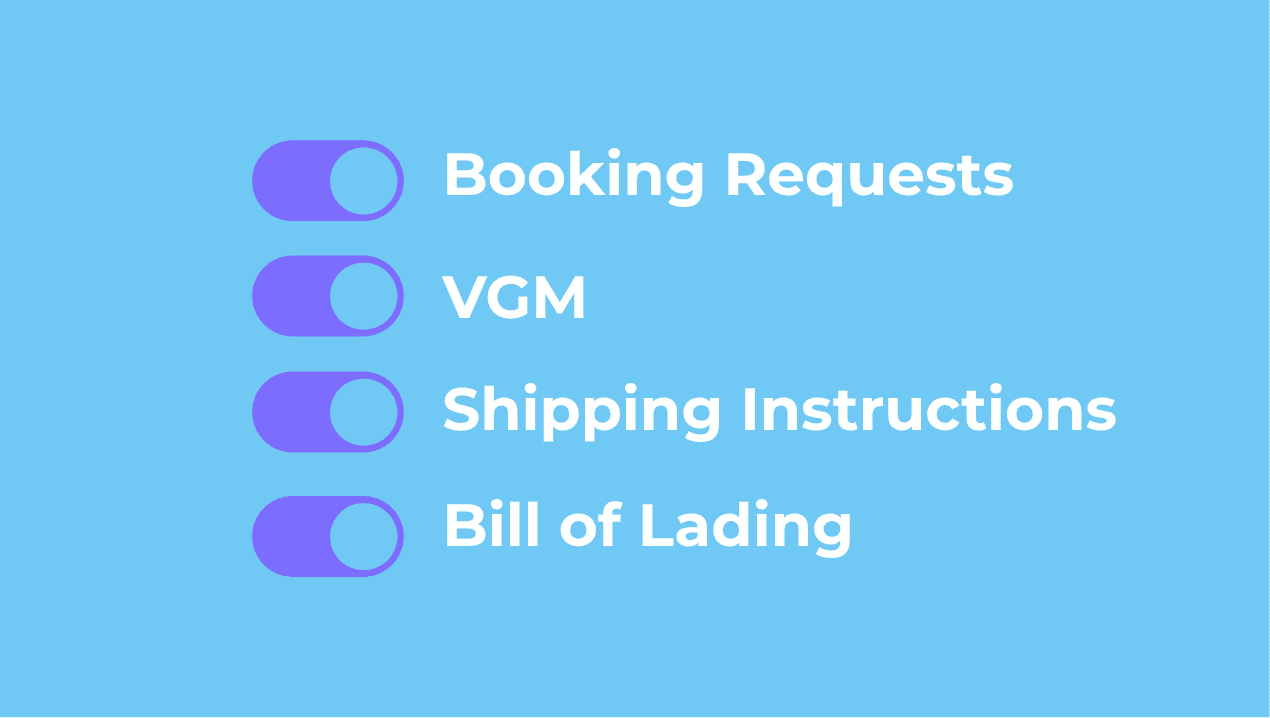

How Digital Platforms Like BuyCo Help: Document workflows, automated tracking, and alerts ensure 95%+ on-time availability of documents. Timestamped audit trails support compliance and dispute resolution. Clearance times improve 30 to 40%, port storage costs drop, and retailers gain predictability in delivery schedules.

Step 5: Drayage and Inland Transportation

Challenge: The handoff between ocean arrival and inland delivery involves multiple parties: terminals, customs, drayage carriers, truckers/rail/barge, and warehouses.

Consequences: Lack of visibility causes missed connections, delays, and additional D&D fees.

How Digital Platforms Like BuyCo Help: BuyCo provides milestone-based visibility from origin to warehouse, orchestrating shipments across all modes. Automated alerts ensure timely drayage dispatch, while coordinated ocean and inland movements cut pickup delays by 40–50% and prevent avoidable charges. Retailers can focus on exceptions while routine shipments run automatically.

Conclusion

Inbound logistics is one of the most complex and cost-sensitive parts of supply chain management, but it doesn’t have to keep retailers in constant firefighting mode. Unpredictable arrival dates, reliance on external logistics providers, manual tracking, and fragmented information drive high inventory levels, avoidable fees, and wasted time.

BuyCo connects all supply chain parties on a single platform to enable visibility and collaboration. Acting as a digital and automated 4PL, it optimizes container flows in real time making automatic booking decisions to reduce lead-time variability and limit inventory costs. This allows importers to reduce D&D and expedited costs, optimize safety stock, and free teams to focus on strategic work. With BuyCo, inbound logistics becomes a connected, predictable, and agile operation, turning complexity into clarity and cost into competitive advantage.